Culverts: A Comprehensive Guide for Civil Engineers

Culverts are a critical component of many infrastructure projects, allowing water to flow under roads, railways, and embankments. This comprehensive guide provides civil engineers with key information on culvert design, construction, maintenance, and analysis.

Table of Contents

- What is a Culvert?

- Importance and Purpose of Culvert Construction

- Culvert Design Specifications

- Materials for Culvert Construction

- Location Selection for Culvert Construction

- Culvert Installation Guide

- Culvert Maintenance and Repair

- Types of Culverts for Drainage

- Culvert Components

- Culvert Sizing Calculations

- Culvert Replacement Cost

- Reinforced Concrete Culvert Construction

- Culvert Headwall Design

- Culvert Failure Analysis

- Culvert Inspection Procedures

- Conclusion

What is a Culvert?

A culvert is a conduit or passage that allows water to flow under a road, railroad, trail, or similar obstruction. Culverts come in many shapes and sizes, typically made of concrete, galvanized steel, aluminum, or plastic. Culverts are installed where it is necessary to maintain proper drainage and prevent flooding.

Culverts serve several key functions:

- Allow water to flow under roads, railways, and embankments without washing out the infrastructure or flooding nearby areas.

- Improve drainage along natural waterways, preventing backups and diversions.

- Help control erosion and scouring from water flow.

- Provide wildlife crossings under roadways and other obstructions.

Importance and Purpose of Culvert Construction

Proper culvert design and construction is vital for many infrastructure projects. Here are some of the top reasons culverts are installed:

- Prevent washouts: Culverts allow water flow to pass safely under roads and railways without eroding or washing out the infrastructure. This helps maintain the integrity of roadways.

- Control flooding: During heavy rains or water surges, culverts provide drainage to prevent localized flooding on roads or nearby areas. This protects property and infrastructure.

- Drainage: Culverts improve general drainage and control where and how fast water flows through areas with ditches, streams, or stormwater runoff.

- Wildlife crossings: Culverts can allow safe passage for wildlife to cross under roadways and other obstructions.

- Water flow: Properly sized culverts maintain proper water flow and prevent dangerous backups or diversions of streams or drainage ways.

Culvert Design Specifications

Culvert design requires in-depth engineering analysis to determine proper sizing, positioning, and material selection. Key specifications include:

- Size: The culvert diameter or span needs to be large enough to handle expected water volumes and debris, with consideration of flood events.

- Shape: Common shapes include circular, box, elliptical, and arch culverts. Shape impacts water flow dynamics.

- Material: Concrete, corrugated metal, and plastic are common. Material affects strength, durability, and corrosion resistance.

- Length: Related to roadway width but may be extended to control water velocity and prevent erosion.

- Positioning: Angle, elevation, and orientation impact water flow and need careful engineering.

- Headwalls: Structures used at the inlet and outlet to improve hydraulics and prevent erosion.

Proper hydrological and hydraulic analysis based on water flow volumes will determine the right size and design. Other factors like soil conditions, erosion potential, and wildlife impacts are also considered.

See also Maximize Strength With Proper Column Reinforcement Techniques

Materials for Culvert Construction

- Concrete: Durable, resistant to corrosion and abrasion. Can be precast or poured in place. Reinforcing rebar adds strength.

- Corrugated Metal: Typically galvanized steel or aluminum. Corrugations add strength. Prone to corrosion depending on soil conditions.

- Plastic: Highly resistant to corrosion as well as abrasion from debris. HDPE and PVC common polymers. Can deform if not properly backfilled.

- Fabricated Metal: Smooth steel used for large box culverts or unique shapes. Coating prevents corrosion. Higher cost.

Soil conditions, pH, and potential abrasion from water or debris help determine appropriate materials. Concrete and plastic excel in aggressive conditions while metal must be protected from corrosion.

Location Selection for Culvert Construction

- Natural drainage paths: Position to utilize natural watercourses and drainage ditches.

- Stream crossings: Span entire channel with consideration for high water and debris.

- Flooding patterns: Avoid exacerbating flooding or backups from culvert limitations.

- Land elevation: Position where approach elevations allow smooth water entry/exit.

- Soil conditions: Bearing capacity must support culvert and water loads without settling.

- Erosion potential: Orient to control water velocity and scouring. Use riprap if needed.

- Right of way: Construction access requirements.

For roadways, optimal location balances proper drainage with economy by utilizing natural terrain contours as much as possible. Environmental impacts, flooding potential, and maintenance access must also be weighed.

Culvert Installation Guide

- Site preparation – Clear area and ensure stable, compacted base. Install bedding if needed.

- Excavate trench to required depth and grade. Maintain safe slopes.

- Lower and position culvert sections. Join sections per manufacturer specifications.

- Backfill in lifts with compacted granular fill. Do not damage culvert.

- Add inlet and outlet headwalls, wingwalls, aprons per design. Improve hydraulics and prevent erosion.

- Protect areas around culvert with riprap, geo-textiles, or other scour countermeasures as needed.

- Conduct flow tests after installation to check for leaks, obstruction, or other defects.

Proper backfilling, compaction, and joints are essential to prevent culvert damage or failure. Always follow design and OSHA safety procedures throughout installation.

Culvert Maintenance and Repair

- Inspect annually and after major storms for signs of erosion, obstructed flow, joint failures, corrosion, or other damage.

- Monitor for sediment buildup and clear regularly to maintain water flow.

- Trim vegetation and roots that obstruct inlets or outlets.

- Repair joints, corroded sections, embankment erosion before it progresses.

- Jetting/cleaning may be needed if significant siltation occurs internally.

- Realign or armor sections if high water erodes soil around culverts.

Major repairs like replacing sections or recoating corroded metal must be performed by qualified contractors. Proactive maintenance can significantly extend culvert lifespan.

See also Key Features of Precast Concrete Panel Installation

Types of Culverts for Drainage

- Circular Culverts – Round pipe culverts made of concrete, corrugated metal or plastic. Most common and economical type.

- Box Culverts – Rectangular or square culverts. Allow more water flow capacity than circular ones. Made of concrete or metal.

- Arch Culverts – Curved semi-circular shape. Can handle greater volumes and debris than circular culverts. Concrete or metal.

- Elliptical Culverts – Oval shaped with improved hydraulic capacity over circular. Concrete, metal or plastic materials.

- Bottomless Culverts – Span streams without disturbing the natural channel. Used for wildlife crossings or sensitive habitat

Culvert sizing, positioning, and use of headwalls/aprons also impact drainage performance. An engineer determines the optimal design based on flow volumes, terrain, and other factors .

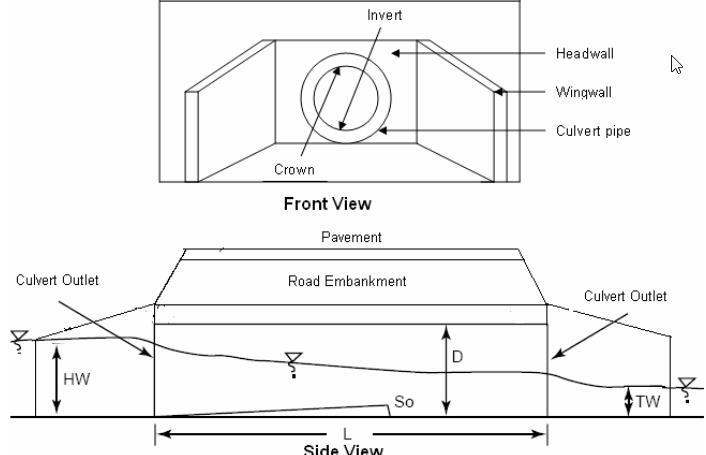

Culvert Components

- Pipe Sections – The main conduit sections that water flows through. Multiple sections joined together.

- Headwalls – Structures at the inlet and outlet to retain and protect the embankment slopes.

- Wingwalls – Side retainers that extend out from the headwalls to contain the embankment.

- Aprons – Slab section at the outlet to prevent scouring and undermining.

- Trash Racks – Steel bar screens that prevent large debris from entering the culvert.

- Flared End Sections – Wider sections attached to the inlet and outlet to improve hydraulics.

- Cutoff Walls – Underground concrete walls around the culvert to prevent water seepage and piping erosion.

Proper selection and design of the culvert components helps optimize performance and prevent failures.

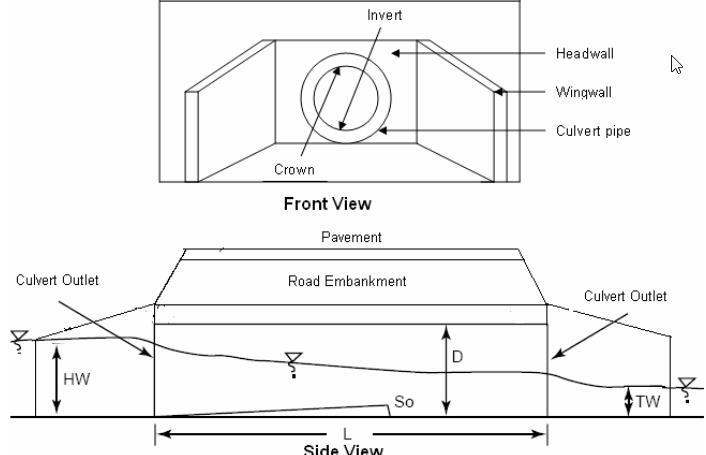

Culvert Sizing Calculations

- Expected water flow volumes based on the drainage area and rainfall data

- Design storm frequencies such as 10-year, 25-year or 100-year flood events

- Allowable headwater elevation and outlet water velocity

- Culvert material, shape, roughness, and inlet configuration

- Allowance for debris and sediment accumulation over time

- Future development or changes in upstream drainage areas

Proper engineering software models water flow dynamics through the culvert options and determines adequate sizing. Oversizing for future conditions may be prudent in some cases. Undersized culverts can lead to catastrophic failures.

Culvert Replacement Cost

Typical factors affecting culvert replacement cost include:

- Culvert size and material

- Site conditions and preparation needs

- Excavation and trenching costs

- Bedding, backfill, and compaction

- Headwalls, wingwalls, and other accessories

- Location and access limitations

- Labor and equipment rates

As a rough estimate, small (36-60 inch diameter) culverts in standard conditions may range from $40-$60/linear foot. Large box culverts can range from $200-$500/linear foot. Unique site conditions, extensive excavation/shoring, or difficult access can increase costs.

Reinforced Concrete Culvert Construction

Reinforced concrete is a very common culvert material due to its strength and durability. Construction involves:

- Casting cylindrical or other shaped sections with reinforcing steel bars (rebar)

- Rebar provides tensile strength while concrete provides compression strength

- Controlled concrete curing to achieve desired strength

- gasketed joints between precast sections to seal against water leakage

- Backfilling with granular fill and compacting around the culvert to support loads

- Use of concrete headwalls, wingwalls, and aprons as needed

See also 10 Ideas of Vaulted Ceilings

Concrete culvert sections are manufactured by commercial precast concrete companies to project specifications or can be cast on site. Quality concrete mix design and curing are essential for performance.

Culvert Headwall Design

- Material selection (concrete most common)

- Inlet edge configuration to control water entry

- Height and side taper to direct water and contain embankment

- Apron size and depth to prevent undermining

- Weep holes to relieve water pressure behind walls

- End treatment like wingwalls to contain embankment

- Riprap, velocity dissipaters, or other scour countermeasures

Headwalls must withstand hydraulic pressure and erosion forces. Extending headwalls beyond the embankment profile helps prevent bypass flow and bank erosion.

Culvert Failure Analysis

- Erosion or washout: Insufficient hydraulic capacity, excessive velocity, or inadequate bank armoring.

- Piping failure: Water seepage through backfill particles leading to void formation and collapse.

- Overtopping: Inadequate height or hydraulic capacity leading to flows over roadway.

- Structural collapse: Excessive deflection, joint separation, or corrosion. Inadequate strength for loads.

- Settlement: Inadequate foundation support from soft or unstable soils.

- Blockage: Debris accumulation or sedimentation obstructing flow. Lack of maintenance.

A forensic analysis is typically needed to determine the failure sequence and root design, construction, or maintenance issues when failures occur.

Culvert Inspection Procedures

Regular inspections are crucial to detect issues before they lead to culvert failure. Inspection procedures include:

- Visual check for orientation, deflection, joint condition, corrosion, erosion, leaks, or other damage.

- Monitor for debris accumulation and siltation that reduces capacity.

- Check for piping voids or sink holes developing in the embankment.

- Measure remaining structural thickness if corrosion is evident.

- Document with photos and detailed notes any observed distresses or changes over time.

- Inspect after major storm events for washing out or other sudden damage.

- Perform mandrel or camera inspection if needed internally.

Thorough documentation provides the basis for maintenance and repair decisions before problems progress.

Conclusion

Proper culvert design, construction, and maintenance is critical for infrastructure projects dealing with water drainage challenges.

Culverts must meet stringent hydraulic capacity, strength, and durability criteria based on engineering analysis of the site conditions and water flows.

Ongoing inspection and maintenance enhances culvert performance and lifespan. This article provides civil engineers with comprehensive best practice guidance spanning the full culvert life cycle.

Carefully following these recommendations will lead to successful culvert installations that provide many years of reliable service.

N Lavanya

Lavanya is a passionate content writer about Structural Design, Grouting, Columns, Beams etc. She has 5 years of experience in teaching in Civil Engg. She enjoys writing complete guides and tips. Her passion is in building materials, construction standards, foundation design and building codes.